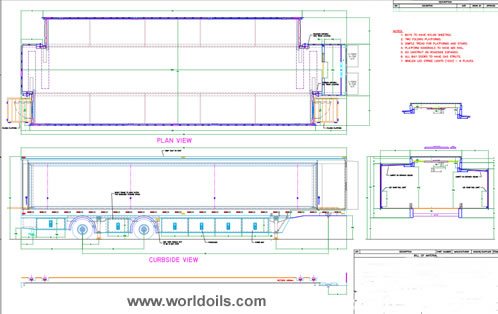

Equipment name: Dual Expanding Side Mobile Marketing Display Trailer for Sale

Category: Disaster Relief Trailers

Specifications:

1.0 Overall Scale: Chassis and Operations Enclosure These dimensions do not exceed the legal limitations of any jurisdiction in 1.2 Trailer Chassis Specifications 2.0 Chassis Weight and Axle Loading 3.0 Body Construction: Methods and Materials All aluminum-to-steel joints are insulated with High Molecular Density Aluminum skin shall be .090 at bulkheads and sides. Fabrication and Construction practices shall utilize proprietary methods of This is a proven design that allows for stress to be distributed evenly throughout This structure was developed for the US Military through computer stress analysis The Universal Composite Trailer Chassis meets the following Industrial, US ASTM B209 - Industry Standard specification for aluminum and aluminum- Body Filler products shall not be utilized in any weight or stress-bearing Proprietary Methods and Materials 3.1 Floor Frame shall incorporate: 3.2 Wall and Bulkhead Construction shall incorporate: 3.4 Roof Construction shall incorporate: 3.5 Exterior Finish: 3.6 Axles and Suspension 3.6.1 Axle Configuration 3.6.2 Wheels and Tires 3.7 Proprietary Expanding Side Mechanism 3.7.1 Method of Operation - Proprietary construction shall operate by means of a manual crank, located at 3.7.2 Expanding Mechanism Floor Description Multiple panels (as opposed to one or two heavy, large panels), shall enable the 3.7.3 Expanding Section Anti-Icing Measures 3.7.4 Expanding Sides 4.0 Undercarriage Storage Bays (Belly Bays) Quantity 5 to 7 Storage Bays shall be provided for each side of vehicle, - Ground Clearance shall be 12” between Kingpin and Tandem axles 4.1 Special Design Features 4.2 Material 4.3 Weatherproofing/Security 4.4 Equipment to be permanently stored in Storage Bays shall include: Custom Designed Aluminum Power Frame, which shall contain all power Extreme care in engineering shall be in place to insure a minimal 5.0 Exterior Doors 5.1 Personnel Doors, Entrance Stairs Construction shall incorporate: 6.0 Exterior Functional 6.1 Leveling System: 6.2 Exterior Lighting 6.2.1 Clearance Lighting shall be provided and installed 6.2.2 Exterior Operations Lighting 7.0 Interior Construction: Methods and Materials General: Final layout and determination of production area to be designed by Client and us upon 7.1 Interior Frame Construction - All interior construction shall be fastened to .125” T-6061 Aluminum - Floor to be constructed of 3/4” Lite plywood 7.2 Operations Area Construction 7.2.1 Display Area 7.3 Interior Lighting 7.4 Fit and Finish 8.0 Environmental Control 8.1 Insulation 8.2 Air Conditioning 8.3 Heat 9.0 Electrical System 9.1 Power System 9.1.1 Power Source: Split Environmental & Technical - System shall provide two completely separate legs of AC; - Each Transformer shall be provided with tap selects Voltage Tap Selects shall provide maximum flexibility for powering Trailer 9.1.2 Power Entrance and Monitoring - Analog meters by Yokogawa shall be provided and installed adjacent to Analog meters by Yokogawa shall be provided and installed on panel in NOTE: We provide and recommend analog meters, as digital meters - Supply and install one (1) 50' shore power cables 9.1.3 Transmission and Termination 9.1.4 Grounding 9.1.5 Low Voltage System The DC distribution system will be fully fused and will power: - Provide and integrate Inverter/Charger Required Options 2) Provide Intergration of internal Modification for client 3) Provide Interior Modification for client to include 4) We will provide and install display tapping plate system for all fixed displays.

Mobile Trailer Vehicle for Sale

Dual Expanding Side Mobile Trailer

Dual Expanding Side Mobile Marketing Display Trailer

1.1 Vehicle Dimensions

- 13'6” High x 53' Length

- Total length including rear bumper and air-conditioning units not to exceed 55’.

- Spread tandem axles 40’ (approximately) from Kingpin.

- Clearance 12” kingpin to tandem axles; 18” to rear bumper

- Empty Shell Interior Dimensions: 100" Wide x 110" High.

- Sure Glide EXP section dimensions, to be determined- up to 46.5’ x 60”

curbside, 42’ x 52” streetside

North America.

- Model #UC 53/102

- Sure Glide Side Expanding System

- L-Stanchion support system

Body and chassis shall be in compliance with legal weight limits and

transportation regulations on all public highways in North America. Commercial

Driver’s License shall be required. No special permits shall be required for travel

on any public highway in North America.

General Statements and Descriptions

The mechanical design and construction of the unit shall be such that the

Client, with proper maintenance, can expect at least 15 years of use.

Polymer to prevent corrosion due to galvanic electrolysis.

MIG Welding and chemical bonding. Lord 500 Series Acrylic Adhesive

shall provide extremely high impact rating and extreme resistance to

thermal and chemical stress.

the entire structure; Neither extreme conditions during travel nor lever-action

physics due to the Sure Glide side shall compromise the structural integrity.

- Framed structures will not concentrate the stress at one singular point

- No distortion or twisting will take place; especially regarding the Upper

Coupler Plate where the kingpin is located

model design by SDRC, San Diego, CA.

Government, and US Military standards:

alloy sheet plate.

AWS D1.1 - Structural Welding Code for Steel.

AWS D1.2 - Structural Welding Code for Aluminum

CF Title 49 - Transportation, US Federal Highways

FED-STD-595 - Federal Standards for Paint

MIL-STD-810E - US Military Standards Environmental & Engineering Guidelines

MIL-STD-454 - US Military Standards Workmanship

MIL-STD-1472 - US Military Standards Human Factor Engineering

component of the aluminum body.

- Formed and steel hat sections into Monocoque design.

- 90ksi min. high tensile steel 4” I-Beams

- 90ksi min. high tensile steel 5” I-Beams at leveling legs & bogie frame

- .032” 3003 aluminum sheeting

- additional proprietary methods and materials

- 12 ga. Galvanneal seal around door jamb and openings

- 1 ½” extruded aluminum hat channel extruded wall studs

- Sections on 16” centers, 1 ½ hat sections as required

- .063 ” T-5454 Aluminum Sheeting for exterior surface

Aluminum skins shall be .090 on expanding side end walls & .090

at bulkheads

- To be seamless and rivetless, smooth auto type look

- Extruded aluminum top rail sections

- Extruded aluminum bottom rail sections.

- Crucial support on the expanding section side shall be gained through use

of 6” by 16” and by 4” by 12” steel tubing.

- additional proprietary methods and materials

- 1 ½” extruded aluminum hat sections on 24” centers

- Extruded aluminum toprail

- One-piece .032 aluminum skin

Pre-tensioned before application to ensure smoothness

Shall only be riveted around the perimeter of the trailer.

Shall be attached to roofbow by means of industrial adhesive.

Shall prevent loosening and subsequent “canning” (bubbling) due

to contraction and expansion, as will occur if rivets are used to

fasten roof skin to roof bows.

- additional roprietary methods and materials

- Scepter Series

- Full preparation to consist of all caulking,

trimming, sanding, etching (zinc chromatechemical etching agent) and all necessary steps to

ensure overall aesthetic “as-newquality for functional life of vehicle with proper on-going maintenance.

- All steel attach points will be treated with anit-corrosion agent and isolated

form all aluminum surfaces

- 2 coats primer and 1 coat white Aircraft-Grade Acrylic Polyurethane

DuPont Imron paint

- All bay door systems will be finish in side as described above.

- Body to be undercoated with anti-corrosion agent

- Shall incorporate Watson Chalin TA-250-16 Series Tandem axles

- Configuration (subject to change upon Engineering with Client)

- Shall be provided with Watson Chalin Air Ride System, TA-250-16 with

ABS, and rigid axle configuration

- 16” air bags, capacity of 22,500 lb. per single axle.

- Provide and install eight (8) Alcoa Polished aluminum wheels

- Provide Trailer with eight (8) Bridgestone R-280

Manual Crank design shall be constructed such that ease of operation allows

one person to fully extend section with one hand; 9 turns, in no more that 20 seconds.

the rear bulkhead of the trailer.

- The crank shall turn a tubular shaft that extends from the rear bulkhead to the

center of the expanding side drive shaft

- 2:1 gear reduction via chain drive fro crank shaft to drive shaft.

- The tube shall be connected to four (4) bearings; with two (2) linear bearings

at each end of the expanding section.

- This connection shall be rack & pinion, to ensure that each end of the

expanding section travels in a parallel fashion;

Expanding section shall remain square upon opening and

closing.

- Large, Internal Security hardware, operating on a cam-style lever principle,

shall aid in sealing the Sure Glide section tight to trailer for travel

- Shall be comprised of six (6) folding panels by Plascore.

- Panels shall store folded against the interior wall of the expanding section.

- Each panel will be held in place by a large, tempered knobbed bolt, which

shall thread into a receiver securely fastened into the expanding section wall

easy set up and strike of the expanding section floor manually.

- Expanding Section roof shall be constructed with 2” slope from trailer outward

- A system of heating strips shall be employed to keep expanding section roof

free of ice and snow when extended.

low-wattage strips shall maintain the roof skin of the expanding

section within a temperature range of 45 to 75 degrees Fahrenheit

(fluctuation due to proximity of any given space on roof to location of

heat strip.)

Shall prevent snow/ice accumulation, in conditions ranging from

freezing rain to 6”/hour snowfall.

- Trailer System shall include a second side system as defined in Section 3.7.1,

3.7.2 and 3.7.3

Dimensions to be determined targeted as follows

Curbside 46.5’ long x 60” expansion

Streetside 42’ long x 52” expansion

General:

Shall be integrated into the skirting around the perimeter of the vehicle,

beneath the chassis frame, such that the body is streamlined.

dependent upon Client needs in terms of size of each Storage Bay.

- Ground Clearance shall be 15-18” aft of rear axle

- Bay floors shall be of “sweep-out” construction, with no raised edges to

pool water or obstruct loading.

- Bay interior to be obstruction-free with the exception of 1” steel tube

supports, which shall be in line with the exterior dividers between the bay

doors

- To include 3/8” x 4” “Rub Rail” guards that extend ½” laterally beyond the

bay doors for protection in cornering situations.

- To include 3/8” x 3” x 4” Skid Rail for thorough protection in bottom-out situations.

- 10-gauge T-6061 Aluminum

- 2” x 4”aluminum c-channel construction

- Bay interior to be constructed of .090 Aluminum to prevent load shifting,

and enhancing appearance when bay doors are open

- Aluminum structural integrity exceeds demands of Remote Television

Operations

- 800 lbs. lighter than similar Storage Bays constructed of Stainless Steel.

- Furgocar 14” integral locking handles operating by a locking cam-style

lever mechanism.

- Perimeter of each bay door shall seat on 90 degree exterior surface

and trimmed in crushable gasket, rendering the bay waterproof.

- Doors shall be held in the “open” position by means of gas charged

struts; the geometrical positioning of which shall aid in both opening and

closing.

- Hinges to be stainless steel, continuous piano hinges.

Isolation Transformers, which shall surrounded by an expanded metal

screen, painted safety yellow.

entry panels, tap switches, analog meters, and all other elements of

Main Power Control Panel. Rear of frame shall be protected by means of

an expanded metal screen painted safety yellow.

power system foot print.

- Quantity two (2) 32” wide personnel door

- 2” x 2” x .125” T-6061 Aluminum Alloy square tubing

- .125 T-6061 Aluminum Alloy skin

- Door frame- Galvaneel Steel

- Reinforcement to prevent bowing shall be gained through use of 5” aluminum

hat channel

- Shall be supplied with Yale panic-bar exit devices and LCN single-action track

door closers (with no protruding “elbow” extending into operations interior).

- Stainless steel plates shall be mounted beneath (hand wear) exit device and

at bottom of door (kick wear) to guard against wear upon repeated exits.

- Custom manufacture10-gauge aluminum “Grip Strut” safety grating expanded

metal stairs; stairs shall be full width (36”)

- Personnel Stairs shall be height adjustable by means of knurled knob which

shall fix sliding feet. No spring mechanism, which is subject to corrosion,

shall be employed.

- One (1) handrail shall be custom manufactured and provided for each set of

stairs; to be constructed of extruded T-6061 Brushed Aluminum Alloy round

tubing, .125” wall thickness.

- All rails, stairs shall be inter-changeable with respect to mounting tabs utilized

to fasten stairs to Vehicle.

- Provide and install Jost Manual leveling jacks

Capacity 55,000lbs

18” throw

84 sq. in. foot pad

Bubble levels at each corner of vehicle

Two-speed gear mechanism

All clearance lights as required by DOT Regulation shall be supplied

and installed

Any required reflective strips shall be supplied

Brake Lights, Tail lights, shall be provided and installed

All tail lights, reverse lights, brake lights shall be recessed

Includes high mounted LED tail lights

All lights to be LED

- Strike Lighting

Provide and install eight (8) HID recessed strike lights

Locate one (1) at rear of trailer,three (3) at street side, four (4) at curbside

Under Expanding Rope Lighting

Layouts included in this proposal will be designed to the clients required need

engineering meetings to ensure that Client specifications and particular needs are met

Alloy joists and interior members

- Ceiling to be constructed of 3/8” Lite plywood

- Interior Sidewalls and Bulkheads to be constructed of 1/4” Space Age

Carbon Fiber Polymer and feather plywood

- All freestanding interior walls to be constructed of 3/8” feather grade plywood

- Carpet covered side wall

- 2-Ton carpet

- Chair trim rail

- Sonex grid ceiling

- Endura flooring

- All lighting for operations shall consist of dimmable, recessed, aimable

(Manufactured by WAC, Inc.) lights

Each bank of WAC lights shall be on an individual, dimmable circuit

Lighting shall operate on either DC via provided inverter, or shore AC.

- Fluorescent lighting shall be provided for setup purposes (12v DC), yet shall

be available during operations

- All Custom Manufactured Furnishing to be oak, custom milled,

prepared, and finished

- Floors covering shall be Dura Step .125” rubber panels, pattern and color to

be determined by Client

- All walls shall be supplied with oak chair rail at chair height (29”) with built in

rope deco lighting

- Walls shall be covered with Beulieu Mills “AutoTough” Auto/Marine carpeting

Rubber-backed AutoTough carpet provides R1 increase in wall

insulation

AutoTough carpet will not “unravel” in the manner of tightloop carpet

Two Tone Scheme shall incorporate Client-selected colors that shall

be separated top and bottom by light oak chair rail at 29” height

- Ceiling shall be Sonex Pyramid Acoustic Foam

Sonex Tiles shall reside in custom Light Oak Ceiling Grid

- Flooring to be from G&A custom sample list either Endura Type or Carpet Type

- Access floor panels to match to include aluminum extrusion.

- Insulation factor on walls of R14 in concert with forced-air Air-Conditioning

system shall provide environmentally secure environment

- Provide and install full thermal insulation on outer walls, floor, doors and ceiling

Insulation to be Blue Dow 2” Owen Corning Polystyrene

Includes continuous vapor seal

PolySeal foam to ensure vapor-tight insular seal

- Insulation factors as follows: R14 walls, R14 ceiling, R14 floors, R9 doors,

and R2 door seals

- Supply and install two (2) three phase operation Marv – Air 5-Ton Wall

mount air conditioning units

- To include Winter Opps system with variable speed motors and

compressor to –10°F.

- To include accumulator system to eliminate high head pressure

- Full H.G.B.P. to 0° cooling

Shall be mounted on front bulkhead of Vehicle

Separate control panels will be located inside the trailer, with both fan

and thermostat operation Visions System.

Ample access for maintenance will be provided by means of side door

panels on the units themselves.

Full digital read diagnostic system thermostat

Refrigerant to be environmentally friendly R-410

- Visions Thermostat System with multiple temp sensor and digital

system

- Units shall include integral 5,000 Watt heating units

The Vehicle shall be powered by means of a 200A power source. Shall be

capable of being powered by means of:

Technical shall power all baseband, broadcast, RF equipment,

and specified receptacles

Environmental, which shall power all lighting, air conditioning,

and specified receptacles.

To include one (1) power meter in bay system, analog and digital.

- Two (2) Hevi-Duty SOLA Isolation Transformers shall be provided and integrated

One (1) 10kVA for Technical loads

80A circuit breakers integrated

One (1) 45kVA for Environmental loads

150A circuit breaker integrated

Voltage taps shall step through positions of 190, 200, 210, 220,

240, and 270 Volts.

Voltage tap shall be selectable by means of Kraus & Naimer Tap

Select switches

from most available on-site power sources.

the input connectors, monitoring:

Amperage

Voltage

Cycle

vehicle interior, allowing monitoring during operations of:

Amperage

Voltage

Cycle

may not function at extreme temperatures

Entertainment rated 200A 600V

Provide four (4) “pig-tail”s

Supply and install Cam-lok power input connectors and panel, adjacent

to monitoring panel

- All Electrical wiring to utilize THHN insulated stranded copper wire

All Electrical wiring to be numbered ends and length in strict

accordance to “as-built” drawings which shall be provided to the Client

All Electrical wiring shall be dressed in accordance with highest

industry standards

All wire runs shall be routed through EMT and flexible conduit.

- Provide and install Hubbell wall receptacles in Operations Interior

Receptacles powered by the Technical leg shall be white in color, and

complete with grounding to technical ground system

Receptacles powered by the Environmental leg shall be ivory in color

These outlets shall be located in areas specified by the Client in

Engineering meetings with us such that specific Client needs are met

- Provide and install Hubbell GFI protected weatherproof duplex outlets,

location and number to be determined by the Client.

- Grounding of the technical equipment within the vehicle shall follow standard

grounding practices

- A 12V DC system shall be provided and integrated

Power Source for 12v DC shall be two (2) Group 27 deep cycle

batteries to be housed in a vented, anti-corrosive enclosure.

Interior lighting, activated by a mechanical timer located at

personnel door such that interior DC powered devices will not

be unintentionally left running

The strike or set-up lighting system

Lighting in Belly Storage Bays

Audio/Video Bulkhead enclosures

81-0153-12 Fleet Power 1500-12MP

Rated 1500W at 120VAC

Shall power all selected interior lighting

1) We will provide and install a 30kVA Martin Diesel Generator

which will include

Bay intergration

WIsper Matt Sound Isolation

Critical Muffler Group

Quite pac intergration

72 hr fuel cell at 75 % capacity

Light Modification

Client Specified equipment

Display Modifications

Display Tie Down Systems

Custom Greeting area with workstation

If you cannot find the vessel, crane, rig or equipment that you need,

please send us an email to mail@worldoils.com stating your

requirements and we shall find it for you.

--------------------------------------------------------------------------------------------------------------------------------

Search words (for official use only) :

Mobile Marketing Display Trailer for Sale

Mobile Trailer Vehicle for Sale

Dual Expanding Side Mobile Marketing Display Trailer

Trailer Vehicle for Sale

--------------------------------------------------------------------------------------------------------------------------------

Select equipment to compare...