Equipment name: Coiled Tubing Unit - Hybrid Top Drive for Sale

Category: Coiled Tubing

Specifications:

Hyrbrid Top Drive Coiled Tubing Rig for Sale in Canada Note : The maximum capacity of the trailer suspension is 40,000kg. When the CT Booster Axle High strength steel, T-1 fabricated frame, low profile design with 9 air bags controlled with Capacity : 45,000lbs Suspension : Air over Peerless rubber bushed walking beam suspension. Legs(2) : Holland LDG700-212 dual pin drop leg assembly. Axles(2) : Rim/Wheels : 10 hole steel Unimount wheels, aluminium machine finish Tires : 275/70R22.5 Michelin XTY-2, 16ply. Electrical : CMVSS approved with seal beam lamps.LED. Air : CMVSS approved Sign Pockets : Pockets on back of light box for wide load sign. Mudflaps : Peerless 24” rubber Weight : 9500lbs. (4,318 kgs) +/-3% Mast load capacity (Injector) : 80,000 lbs Range III capacity Dimensions are based on the following : Crown sheave assembly : Travel block : Two-sheave 50-ton capacity (integral with top drive) Crown shaver : installed at crown Make : Stewart & Stevenson Model : m 80 Maximum pull* : 80,000 lbs Snubbing capacity : 35,000 Tubing speed* : 95ft/min Maximum tube size : 3 ½” Hook load : Double acting load cell mounted in injector frame Power source/drive : See A/C Drive below. Main chain drive via A/C electric motors, chain tension, traction 2 – 125hp AC motors in combination with 2–1:1 right angle planetary drives. Motor manufacture : Reliance Electric General features : Force air cooled, drip proof, fully guarded design with encapsulated windings, high temperature Gooseneck : 120” radius Support rollers : 2 7/8” (steel) Hold Down rollers (3) : 2 7/8” (steel) Straighter assembly (optional) : Three roller system – mechanically adjustable Mounted at base of gooseneck to provide improved spooling of coil onto storage reel. Hydraulic Guide Rollers (rabbit ears) : UMHW – one set mounted at lead support roller Consists of a two-part tube assembly that telescopes and is sealed to one another by Capacity : Pack off to 1,000psi at 2,500 psi hydraulic pressure Size : Accommodates 3 ½” OD coiled tubing The Tubing Storage Reel assembly has a maximum capacity of 1000m of 3 ½” coil or 4605m of 1-3/4” dia. Tube 3620m of 2” dia. Tube 2617m of 2-3/8” dia. Tube 1500m of 2-7/8” dia tube Reel mounting : Integral with trailer allowing for the storage reel to be recessed between Drive group : A/C motor, in-line brake, planetary, chain transmission Fluid connection : Removable wash pipe through reel axle-recessed style Internal plumbing : 3” hose – 3000psi (wash pipe to coiled tubing) Eternal plumbing : 3” hose – 3000psi (plumbing manifold to wash pipe) 1-50hp AC motor in combination with planetary drive and inline hydraulic brake. Motor manufacture : Reliance Electric General Features : Force air cooled, drip proof, fully guarded design with encapsulated winding, high temperature Permanently installed top drive systems including the traveling block, break out – backup tong, Model 240 Top Drive : Maximum Hoist Load : 100,000lbs (rotating) Spindle opening : 3” thru bore with 6 5/8 API regular box Reduction : 5:1 with additional reduction to achieve 13:1 Performance : Maximum continuous torque of 10,000 ft/lbs Maximum intermittent torque of 14,000 ft/lbs Maximum speed of 225 rpm Split Traveling Block : Sheaves : Composite 50.8cm (20”) diameter sheaves for 22mm (7/8”) cable Hoisting capacity : 45,400kg (100,000lbs) Guide assemblies : Nylantron insets to suit tube rails on inside of derrick legs. Guide assemblies keep top drive Bales and Elevators Kick out cylinders : Mounted below the top drive connected to the bales. These cylinders allow for the bales with Bales : One set of 84” bales Elevators : Customer supplied Mud Swivel Assembly Mud inlet swivel : 76.2mm 93 in) mounted directly to top drive. Rated 31,000kpa (4500 psi) working pressure Gooseneck : 76mm (3 in) to support Kelly hose. Floating Cushion Sub Floating cushion sub : Provides a telescoping action that minimizes axial loading while making or breaking tool joints. Hydraulic Back-up Tong Back up tong : Hydraulically actuated tong assembly mounted below top drive to assist in breakout/make-up Mud Plumbing : Kelly hose : 2 ½” – 2400 psi (mast candy cane to top drive) A-frame hose : 2 ½” – 2400 psi (plumbing manifold to mast candy cane) Whip check : Certified whip checks supplied at both ends, as per Customer Specifications Special Request : All fastners on the top drive assembly are secured A/C Drive for Top Drive (supplied by customer) Powered by 2-125hp AC electric motors. Motor manufacture : Reliance Electric General features : Force air cooled, drip proof, fully guarded design with encapsulated windings, high Drawworks Winch A/C motor driven winch is mounted approximately 2/3 the way up the derrick on backside. Capacity : 100,000lbs with 4-line block (based on a bare drum) Block speed : 200 ft/min (based on a bare drum) Brakes : Multi disc spring applied brake for emergency or parking Dynamic braking on the DC Storage reel capacity : 400ft (for “slip and cut”) Drive group : A/C motor through parallel 20:1 reduction gear box Load cell/WOB : Load cell clamped to deadline (supplied by customer) Auto driller : Responsibility of customer 400 hp A/C motor in combination with a 20:1 reduction gear drive. Single speed. Motor manufacture : Reliance Electric General Features : Force air cooled, drip proof, fully guarded design with encapsulated windings, high temperature Winches Winches are sized for appropriate lift and cable life as per application. The main winch is used Main winch : Capacity : 7,250 lbs Wire rope : 9/16” dia. Lubricator winch : Capacity : 2200 lbs Wire rope : 3/8” dia. Substructure The substructure is integral with the mast “A” frame and is permanently fixed to the rear of Rotary table : Hydraulically drive and controlled ENID rotary table BOP handling : 2 cylinders mounted under floor to raise and lower BOP. Manual controls in cellar. Make-up & Breakout : 2 cylinders mounted vertically in substructure Work floor : Steel checker plate with traction paint. Includes handrails with kick plates as necessary. Rotary Table The rotary table’s primary function will be to assist in the makeup and breakout of jointed Rotary table : ENID Drill Systems Inc. – Super Bowl Static weight specs : 45,500kg (100,000lbs) Rotating weight specs : 45,500kg (100,000) upto to 50rpm Dimensions : 81cm x 122cm x 21cm (32” x 48” x 8 5/8”) Weight : Table – 625kg (1,400lbs) Bushing – 140kg (320lbs) Round opening : 40.6 cm (16”) Drive square : 46.7 cm (18 ½”) Drive : Hydraulic Performance : 2,250 Nm (1,662 ft/lbs.) @ 125 rpm Master Bushing for Rotary Table : Controls Rig control is achieved through a PLC based 24v DC electric over hydraulic system. Operation Hydraulic Power Package Power Source : 60hp A/C electric motor Skid mounted Gearbox/pump drive pumps : Direct coupled to motor 1- Permco P197 1 – Rexroth A10V Hydraulic tank : Fabricated steel with rubber isolation mounts Cooler assembly : Remote mounted on trailer deck with A/C motor driven fan. 1-60hp AC motor in combination with twin pad pump drive. Motor manufacture : WEG General features : Force air cooled, drip proof, fully guarded design with encapsulated Steam Heaters Two Ruffneck steam heaters are supplied with the rig to heat the BOP in winter. In addition the Mud Plumbing Mud plumbing is provided for both drilling systems – drilling with coil or jointed pipe A Ridged plumbing : 3”, 3,000psi (kill line and fire proof hose 2”) Gate valve (3) : 3” Internal reel plumbing : 3” hose – 3000psi External reel plumbing : 3” hose – 3000psi Kelly : 2 ½” hose – 2400psi A-frame : 2 ½” hose – 2400psi BOP Plumbing BOP plumbing consisting of quick connectors, hoses and steel piping in order for the Responsibility of the customer Water/Steam/Air Lines Water and steam lines with connection points to interface with customer supplied boiler and Misc. Equipment Effective Date of Inventory : April 2007 Rig depth rating 1,500m using 89mm Range 2 drill pipe Rig depth rating 1,500m using 73mm Coiled Tubing Number of loads (w/boiler) 10, No crane required Make : Foremost Drum : 508mm Maximum Hoisting Capacity : 44,500 daN Number of Hoisting Speeds : Single speed Auxiliary Brake Type : N/A B. Rig Power : Make : 2 ea. Catepillar 3456 Peak Power : 2 @ 455kW 1800rpm C. Derrick : Make : Foremost Type : Coil/Top Drive Height : 19.5m Normal Number of Lines Strung : 4 Maximum Allowance Working Load (API) : 44,500 daN w/ 4 lines Contractor’s Allowable Working Load : 40,050 daN w/ 4 lines Type : 24 Wheel Coil/Top Drive Carrier Maximum Load Capacity Set back : N/A daN 3.88m long Maximum Load Capacity Rotary : 44,500 daN 3.81m wideKB-Guard : 3.8-4.2m Vertical Clearance for BOPs : 3.2-3.5m c/w BOP handling system Make : Enid Drill Systems Inc. Type :Hydraulic Opening : 406mm Contractor’s Operating rpm : Max. : 125 Min. : 0 G. Travelling Equipment : Bails – Make/Model : Web Wilson Manufacturer’s Maximum Allowable Load : 87,000 daN Elevator – Make/Model : Web Wilson Manufacturer’s Maximum Allowable Load : 87,000 daN Line Size : 22.225mm Line Type : Shaw’s Dyform Single Line Breaking Strength : 42,260 daN 88.9mm OD, Grade : E75, 18.3kg/m, Conn. 3 ½” IF, 600m c/w2 hydraulic pipe tubs 120.7mm OD, 59.0mm ID, Conn. 3 ½” IF, Joint available 18 Make & Model : Gardner Denver PZ9, Stroke : 229mm Pump powered by : 860kW WEG

Used CT Rigs for Sale in Canada

Coiled Tubing Rig for Sale in USA

Used Hybrid Top Drive Coiled Tubing Unit for Sale

Application

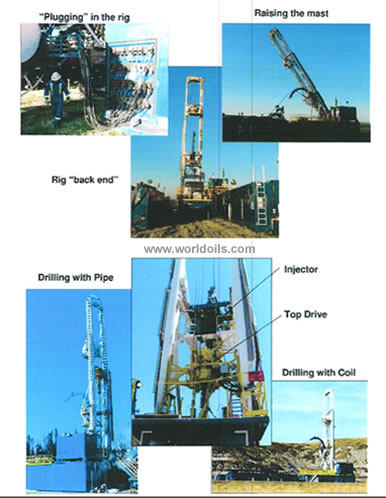

The “CTR-100/80 A/C” is a hybrid Coiled Tubing drill rig with integral

Top Drive for jointed pipe drilling. With a hook load of 100,000lbs.

(44,000 DaN) at the top driveand 80,000 lbs (35,000 DaN) at the injector,

is specifically designed for drilling depths to :

- 5000 ft (1,500 meters) with 3 ½” diameter jointed pipe

- 5000 ft (1,500 meters) with 2 7/8” diameter coiled tubing

- 8,586 ft (2,617 meters) with 2 3/8”” diameter coiled tubing

- 11,877 ft (3,620 meters) with 2” diameter coiled tubing

- 15,108 ft (4,605 meters) with 1 ¾” diameter coiled tubing

capacity and depth may vary.

General

A trailer-mounted coil tubing rig consisting of a mast with integral substructure/work

floor, drawworks, storage reel with level wind, injector, top drive and A/C powered

hydraulic system. The major rotating components such as the top drive injector and

drawworks area powered by A/C electric motors. Linear devices in addition to smaller

rotary components such as cylinders and level wind drive are hydraulically powered.

The rig is designed for drilling applications and includes means for drilling with either

coil tubing or jointed pipe in addition to running casing tubulars. The injector is fixed at

a set height within the mast. Drilling with jointed pipe or running of casing can be

achieved without moving the rig by moving the injector forward allowing the top drive/

traveling block assembly to pass clear of the injector. All drilling functions are

controlled via a PLC based system located in the rig doghouse. Set up functions only

are achieved through manual controls mounted on the rig trailer.

Height - 17’ with injector retracted

The trailer is a high yield steel construction 65 Ton 24 wheel trailer with air ride

suspension. The gooseneck is sufficient in length to accommodate a typical tandem

axle or 16 wheel jeep and has provisions for a booster axle (due to the design of the rear

trailer suspension it is recommend that the booster axle be supplied – jeep is optional).

The mast crown extends more than 10’ pas the gooseneck pin ad may require the use of

a pilot vehicle while moving over public roadways.

Configuration : Single Drop

Dimensions (approximate) :

Six total (2 front with single pontoon and 2 at mid trailer with single pontoon and 2 rear

complete with individual landing pads). Front and mid outriggers are hydraulically locked.

Rear outriggers are hydraulically locked with additional mechanical backup. All outriggers are

removable for ease of service.

Weight (approximate) : 30,865 lbs (14,000kgs)

rig is loaded with approximately 1500 meters of 2 7/8” diameter coiled tubing it will

exceed the maximum rated capacity. The Peerless 24 wheel air ride suspension is

rated for a maximum load of 40,000kgs. Any loading above this rating will cause

premature component wear and may lead to a complete failure of the suspension

system. Peerless will not warrant any component of the suspension system of loaded

at any time above the rated capacity.

high volume regulator and accumulator air tanks for equal pressure. Clamp on style adapter

to fir 24 wheel chassis.

K.G.I self-steering axles, 16-1/2” x 7” brakes rated 22,500 lbs., oil seals and air

dampers on tie rods. Haldex auto slacks.

Hub & Drums : 10 stud Unimount hub and drums (longstud)

Mast

The mast is a steel fabricated twin tube design with raising/lowering from two multi-stage

hydraulic cylinders. The mast supports both means of hoisting induced by the injector

and drawworks winch. The mast accommodates the injector at a fixed height. The injector

is attached to a mechanism that hydraulically moves the injector as to provide clearance for

the traveling block/top drive while hoisting of jointed tubulars.

Mast load capacity (Jointed pipe) : 100,000 lbs

Mast casing length :

From top side of rotary table bowl to top side of elevator 55’ 10” (17m). Crown out allowance

– 4’(1.22m).

Two – 20” diameter sheave (one sheave fitted with encoder ring)

One – 24 diameter sheave

Injector (*Note : these specifications are based on the electric drive as quoted below)

and planetary brake are hydraulically operated.

A/C Drive for Injector (supplied by customer)

insulation and bearings suited for vertical applications.

Gooseneck with Swivel Base and Support Frame

Swivel :

lock out pin for transport.

Lubricator/Stripper Assembly

an inflatable rubber bladder. A hydraulically actuated stripper assembly is mounted at one

end of the tube directly below the injector head. The assembly is adjustable for height by

means of a hydraulic winch.

Manufacture : Progressive Technologies

Storage Reel Assembly

1500m of 2 7/8” coil. The storage spool is a plug and play cartridge design incorporating

a level wind spooler system for efficient wrapping of the tubing.

Reel size : 144” OD – 110” ID – 90” width

Calculated Capacity :

Level winder :

Hydraulically driven diamond lead screw, Level wind head is raised/lowered to working

position hydraulically.

the trailer’s main frame rails.

A/C Drive for Storage Reel (supplied by customer)

insulation.

Top Drive

bales, elevators and mud swivel. For thread make up a floating cushion connector is used to

prevent damage to pipe joint threads.

aligned to well center and transfer top drive torque top derrick legs.

elevator to be hydraulically positioned towards the v-door to connect to the drill pipe.

Box and pin connections are cut to customers specifications.

of the drill string. Accommodates tool joints up to 7” OD.

temperature insulation and bearings suited for vertical applications.

bus ( bus is responsibility of customer)

Drum capacity : 400ft.

A/C Drive for Winch (supplied by customer)

insulation.

primarily for lifting BHA components, drill collars, etc from the V-door or ground. The lubricator

winch is for retracting the lubricator assembly from the BOP stack.

the trailer. The substructure floor provides a working area for the rig crew as well as

incorporating a rotary table to assist in connecting of jointed components of the BHA. Two

hydraulic cylinders with cables are provided to operate manual pipe tongs used in the makeup

and breakout of threaded connections. In addition counterweights are provided to assist in the

lifting and lowering of both the makeup and breakout tong wrenches. Two hydraulic cylinders

and traveling dolly system provide a means for which to raise and lower the BOP from the well

head in addition to provide a method for transporting the BOP with the rig between locations.

Structure Capacity : 100,000lbs

tubulars quickly and safely.

46.7 cm (18 ½”) square drive. Internal API opening 13 1/16” top of taper with 4” TPF

of the rig while drilling is done from the control panel situated in the dog house. Rig up is

performed from a secondary location on the drill rig carrier. These controls consist of both hand

operated manual hydraulic valves in conjunction with electric over hydraulic controls.

Rated at 113 deg F

A/C Drive for Hydraulic Power Pack (supplied by customer)

windings, high temperature insulation.

substructure is enclosed with metal sheeting and provisions for securing additional customer

supplied tarps are included. Plumbing and connection points are supplied to tie in customer

supplied boiler.

hammer union connection point is provided at the front of the trailer so the customer supplied

mud system (kicker hose) can be connected. A gate valve is installed to close the system

flow to the coil reel with a second gate valve used to close the system flow to the ridged

plumbing leading to the top drive. These two valves are used to control the flow either for

operation with coil or the top drive. A hose assembly with swivel is used to connect the

plumbing manifold to the wash pipe, which is passed through the axle of the storage reel.

From this wash pipe a hose assembly is used to connect to the coil tubing. A third gate

valve is connected to the plumbing manifold that controls flow to the kill line leading into

the substructure.

customer to connect the NOP stack to the accumulator system (customer supplied).

A bulkhead is located near the gooseneck of the trailer. This bulkhead is equipped with

5 sets of quick couplers suitable in size to connect with the accumulator system. All

couplers are labelled as to their function. From the bulkhead hydraulic hose is run to a

point sufficient in distance from the well centre to meet code. At this point steel line

(or fireproof hose) is run the length of the trailer to just inside the cellar area at which point

it is terminated at a second bulkhead. The purpose of this bulkhead is to allow separate

hoses to be run to BOP stack. From bulkhead in the cellar, fireproof hose of sufficient

length, complete with quick couplers is supplied to connect with the BOP stack (stack

supplied by customer). All hose and fitting sizes, specifications are to be in accordance

with applicable codes and customer requirements.

Lighting

water tank, using non-malleable iron fittings only. In addition, all lines will be wrapped with

fiberglass insulation and aluminium sheeting.

Fall arrestor (1) : Supplied and installed from ladder side of crown

A. Drawworks :

D. Substructure :

Make : Foremost

E. Rotary Table :

F. Swivel : N/A

H. Drilling Line :

I. Drill Pipe :

J. Drill Collars :

K. Mud Pump :

Liner sizes (mm) : 127

Maximum strokes/min : 130

Minimum strokes/min : 1

Manufacturer’s Maximum Pump Pressure (kPa) : 29,900

Contractor’s Maximum Pump Pressure (kPa) : 21,000

Liner sizes (mm) : 140

Maximum strokes/min : 130

Minimum strokes/min : 1

Manufacturer’s Maximum Pump Pressure (kPa) : 24,800

Contractor’s Maximum Pump Pressure (kPa) : 21,000

Liner sizes (mm) : 165

Maximum strokes/min : 130

Minimum strokes/min : 1

Manufacturer’s Maximum Pump Pressure (kPa) : 17,650

Contractor’s Maximum Pump Pressure (kPa) : 16,000

L. Mud Tanks :

Total volume : 49.1 cbm

Active (useable) volume : 38.7 cbm

Pill tank volume : N/A

Trip tank volume : 3.9 cbm

Number of tanks : 1

Number of compartments : 5

Independent Mud Mixing System :

Pump 1 – Type : Mission , Size : 152m x 127mm x 356mm

Pump 2 – Type : Mission , Size : 152m x 127mm x 356mm

Agitator Type : Varco

Number of Agitator : 2

Hole Fill Pump : Brico

M. Shale Shaker :

Make : King Cobra – Varco

Number : 1

Vibrating Speed : 1,800 cycles/min.

N. Mud Gas Separator :

Location : Shaker Tank

Height above mud level : 1.88m (Mud level to top of vessel)

Vessel Diameter : 610mm

Liquid inlet line size : 76mm

Gas outlet size : 152.4mm

Open bottom : Yes

Internal baffles : Yes

NACE Certified : Yes

Blowout Prevention

BOP : Annular

Make : Townsend

Type : T90

size (mm) : 228.6

Pressure Rating (kPa) : 21,000

Nace Trim : Yes

BOP : Pipe Ram

Make : Townsend

Type : T81

size (mm) : 228.6

Pressure Rating (kPa) : 21,000

Nace Trim : Yes

BOP : Blind Ram

Make : Townsend

Type : T81

size (mm) : 228.6

Pressure Rating (kPa) : 21,000

Nace Trim : Yes

HCR Valve : 79.4mm Hi-Kalibre

Kill Line Valves : 51mm

Accumulator :

Academy Services Model# 1-66-3-11

Size : 249.8 litres

Rating : 21,000 kPa

P. Manifold :

a) The Master BOP controls are located at the accumulator and remote controls

located at the driller’s station.

b) Pressure Rating : 21,000 kPa

Choke Line Size : 76mm

Valve Type : Hi-Kalibre

Size : 76 x 52mm

c) Nace Trim : Yes

Q. Light Plants :

Powered by and Output kW – N/A

R. Instrumentation : Pason

S. Boiler :

Make :William Davis

Type : 100hp

Output : 74.5 kW

T. Top Drive :

Make : Foremost

Type : RC240

U. Lubricator/Stripper :

Make : Progresive Tech.

Type : Hydraulic

V. Fuel Storage : 10,000 litres Boiler 5,200 litres

W. Water Storage : 48,000 litres Boiler 21,000 litres

Price & terms : Please enquire using the email form below.

If you cannot find the vessel, crane, rig or equipment that you need,

please send us an email to mail@worldoils.com stating your

requirements and we shall find it for you.

We can arrange delivery of equipment and towage of rigs and vessels where needed.

The details mentioned above are believed to be accurate but are not guaranteed.

----------------------------------------------------------------------------------------------------------------------------

Search words (for official use only) -

Used Hybrid Top Drive Coiled Tubing Unit for Sale in USA

Coiled Tubing Rig for Sale in USA

Hyrbrid Top Drive Coiled Tubing Rig for Sale in Canada

Used CT Rigs for Sale in Canada

CT Rigs for Sale in USA

Rig for Sale - Hybrid Top Drive Coiled Tubing Unit

Hybrid Top Drive Coiled Tubing Unit

Used Coiled Tubing for Sale

--------------------------------------------------------------------------------------------------------------------------------

Select equipment to compare...