Equipment name: CAT 3516B Generators for Sale - New

Category: Generators

Caterpillar 3516B Generators for Sale

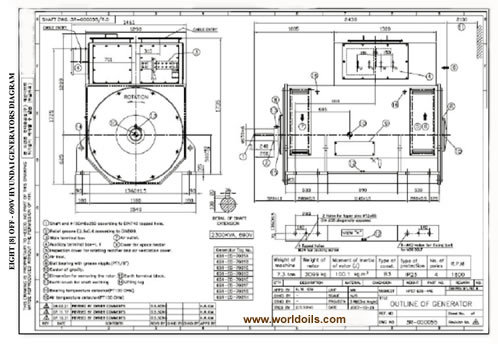

Unused Hyundai Generators for Sale

Marine Diesel Generator - 1800 rpm

Marine Generators - Caterpillar 3516B

Caterpillar Diesel Generator set for Sale

Package :

- 8 / ea. Units 3516B rated @ 1,840-kW cont. 690 volt 60 HZ @ 1,800 rpm

Hyundai Generators

- 3 / ea. Units 3516B rated @ 1,840-kW cont. 440 volt 60 HZ @ 1,800 rpm

Hyundai Generators

- 1 / ea. Unit 3412C rated @ 500-kW emergency standby 440 volt 60 HZ @

1,800 rpm CAT SR4B Generator

- 1 / ea. NEW CAT Synchro System for Gensets.

Description :

Main Engines

8 / ea. 1,840-KW Prime 690 Volt Caterpillar Diesel Hyundai Generator Skids, Containerized

equipped with ventilation insulation and exhaust.

Auxiliary Systems

3 / ea. 1,840-kW Prime 440 Volt Caterpillar Diesel Hyundai Generator Skids, Containerized

equipped with ventilation insulation and exhaust.

Emergency Systems

1 / ea. 500-kW Prime 440 Volt Cat Diesel Cat Generator Skid, Containerized equipped with

ventilation insulation and exhaust.

Main Generator Diesel Skid

- Eight [8] Containers of A-0 in walls and roof to be delivered for Eight [8] Diesel Engine and

Generator Skids for supply of Electrical Power 2,300 kVA, 690 V, 60 Hz.

- Free access distance between engine/generator and container walls to be preferable 600mm.

- Each Container shall have Two [2] A-0 Sliding Doors. One door installed on each side of the

container. When the containers are placed alongside each other, the sliding doors to meet for

entering from one container to the next one. The doors are not to protrude outside the container.

- Each Container has a Ventilation System with registers in and out.

- The Containers are arranged as separate Engine Rooms with Fuel System, external top-

mounted Exhaust System, Lube Oil System, Cooling Water System based on Air-Cooled

Radiator System with Internal Radiators, Starting System, Bilge System, Light, Fire Fighting

System, Instrument, Alarms and Automatic Start/Stop System according to class requirement.

Brackets for installation of Fire/Flame Detectors to be installed.

- Lifting Eyes for Chain Blocks are installed above all Diesel Engines in container for maintenance

work such as lifting in/out pistons or cylinder liners.

- All of the Containers are supplied with One [1] set of Standard Tools for maintenance of the

Diesel Engines. Tools are located at wall-mounted Tool Panel inside the containers.

- All the Containers are equipped with heating according to Class notation. This is to prevent frost

damage of all installed equipment during lay up in winter season with an outside temperature of

20degC.

Main Generator Diesel Engines

- A standard built-on factory supplied Fresh Water Cooling System based on Air-Cooled Radiator

System with Fresh Water Pump, Radiator (in machinery space) with Electrical Driven Cooling

Fans, Electrical Water Heater with Circulation Pump. (Flexible pipe connections to engine)

- A standard built-on factory supplied Fuel System with Fuel Injection Pump, Fuel Feed Pump,

Primary Fuel Filter Duplex Element-Filter with Water Separator, Secondary Fuel Filter, double

walled high pressure Fuel Lines, flexible fuel connections, Woodward Pro Act II Actuator mounted

on engine, Woodward 2301 D (or similar) Electronic Governor.

- The Fuel Oil System includes :

Internal separate A60 insulated Fuel Tank in each container for 8-hours running at 100% load.

Internal A60 insulated Fuel Tank for 18-hours running at 100% load installed in the Emergency

Diesel Generator Container.

- A standard built-on factory supplied Lube Oil System consisting of direct-driven Lube Oil Pump,

Duplex Lube Oil Filter, Bypass Lube Oil Filter, Lube Oil Cooler, Electrical Lube Oil Priming

Pump, also prepared to drain the Oil Sump, Starter Cabinets.

- A standard built-on factory supplied dry Exhaust Gas System equipped with Air Inlet Filters,

Turbocharger, Charging Air Cooler, insulated Exhaust-Manifold, flexible Expansion Joints, and

Exhaust Silencer 35 dBA with Spark Arrestors. Combustion Air Intake is arranged outside.

- Turning Motor or Turning Gear with handle.

- Flexible high elastic coupling fitted to Engine Flywheel and Generator Shaft

- The power stated is valid for conditions in accordance with ISO 3046/1

- Lifting Eyes for transport and installation

- A standard built-in on factory supplied Starting System consisting of Electrical Starting Motors,

Charging Rectifier, Starting Batteries in battery boxes separate starting system for each engine.

The Diesel Engines have a starting battery capacity for a minimum of 3 starts of each engine. The

Emergency Generator has a minimum starting battery capacity for a minimum of 6 automatic

starting attempts and 3 manual starting attempts.

Instrument, Alarms and Automatic Start/Stop System

Main Generator Diesel Control Panel :

Alarm Sensor for :

- Low Lube Oil Pressure

- High Lube Oil Temperature

- High Diff. Pressure over Lube Oil Filter

- High Water Temperature

- Low Cooling Water Flow

- Fuel leaks in double walled Fuel Lines

- Low Cooling Water Level in Expansion Tank

- Charging Air Pressure

- High Exhaust Gas Temperature after Turbocharger

Auto-Stop Device for :

- Low Lube Oil Pressure

- High Water Temperature

- Over Speed

Automatic Start and Shut Down System with following functions :

- LCD display showing voltage, rpm, oil pressure and temperature, water temperature, Charge

air pressure and exhaust temperature after turbo.

- Automatic start attempts according to class requirement.

- Automatic shutdown for low oil pressure, high water temperature and over speed

- Start Switch

- Stop Switch

- Hour Meter

- Converter for serial communication

- Common Alarm and Shutdown Alarm

- Stop System

- 24 V Stop Solenoid Valve. The Control System includes interface prepared for a Dynamic

Position Keeping System and a Power Management System arranged according to Lloyds

Rules & Regulations.

Additional Information :

Diesel Oil :

The Diesel Engine complies with conditions in accordance with ISO 3046/l

Lubricating Oil :

Lubricating oil shall comply with the Diesel Engine manufacturer’s recommendation.

Viscosity Class SAE 40 (ISO VG 150).

Content of additives should meet the requirements of MIL-L-2104 C or API Service CD.

Turbocharger : The oil may be mineral oil or synthetic oil having a viscosity of 30-55 cSt/50deg.C.

Output particulars :

8 / ea. Engines :

Engine output Min 1,920-kW

Output speed : 1,800 rpm

3 / ea. Engines are dedicated to the Auxiliary Power Systems :

Engine output Min 1,920-kW

Output speed : 1,800 rpm

Main Generators

All the Generators are supplied with :

- Automatic Voltage Regulator

- Equipment for parallel operation

- Anti Condense Heater

- PT-100 temperature sensors in windings

- PT-100 temperature sensors in bearings

- MCT Brattberg cable entry in container

- Termination Box for power cables

- Foundations.

All Auxiliary Engines and Emergency Generator are as follows :

- Engines and Generators are lined up on a common steel frame (skid), designed for being lifted

in/out of machinery space for transport ashore in case of engine/generator breakdown.

- Vibration Dampers for mounting between skid frame and container floor. This to avoid vibrations

in supporting structures.

Hyundai made Generators to the Diesel Engines are summarized :

- Eight [8] Generators for Prime Power

- Location : Indoors

- Electrical Rating : 1,840-kW

- Speed : 1,800 rpm

- Frequency : 60 Hz

- Power Factor : 0.8

- No of phase : 3 ph

- Supply Voltage : 690 V

- Excitation : Self excited

- AVR : included

- Mounting / Enclosure

- Protection : IP 23

- Bearings : Re-greasable

- Cooling : Air Cooled

- Accessories / Fittings

- Temp sensing : 6 off stator RTD (PT 100) in windings

- 1 off RTD (PT 100) per bearing

- 1 off RTD Cooling air in

- 1 off RTD Cooling air out

- Anti Condensation Heater : 2 x 100 W, 220 V, 1 ph

- Water leakage detection : included

Instrumentation & Control

The Eleven [11] Auxiliary Engines are configured to be controlled and monitored from a central

Integrated Control System (ICS).

Interfaces are realized by means of distributed I/O modules communicating over a redundant bus

system. Local Control of all main functions for the engines with Auxiliary Systems is included.

The Control System is laid out also to monitor and interface all critical failures and alarm

situations for the Engines, Generators and Auxiliary Systems.

Price & terms : Please enquire using the email form below.

If you cannot find the vessel, crane, rig or equipment that you need,

please send us an email to mail@worldoils.com stating your

requirements and we shall find it for you.

We can arrange delivery of equipment and towage of rigs and vessels where needed.

The details mentioned above are believed to be accurate but are not guaranteed.

-----------------------------------------------------------------------------------------------------

Search words (for official use only) -

Caterpillar 3516B Generators for Sale

Unused Caterpillar Marine Generators For Sale

Caterpillar Generators For Sale

Diesel Generators for sale - Caterpillar 3516B

1800 rpm Hyundai Diesel Generators

-------------------------------------------------------------------------------------------------------

Vessel Monitoring Software

Offsore Rig Monitoring Software

Mobile Hospitals

Field Hospitals

LDPE Recycling

Reichdrill 650 Drilling Rig - For Sale

Longyear 44 Core Drilling Rig - For Sale

Generic Longyear 44 Wireline Core Drilling Rig - For Sale

Generic Longyear 44 Core Drilling Rig - For Sale

Diedrich Rubber Track Sonic Drilling Rig - For Sale

Sandvik Cubex 5200 Core Drilling Rig - For Sale

Sandvik Cubex 6200 Reverse Circulation Drill Rig - For Sale

Doosan XHP750 Air Compressor & Duramast Drill Rig Package - For sale

Gus Pech R-15 Brat-A-Sonic Drilling Rig - For Sale

Generic Top Head Drive Drilling Rig - For Sale

Soilmec SM 401 Rock Drill - For Sale

Klemm 702-2 Micropile Crawler Drill - For Sale

Schramm T660 Drilling Rig - For Sale

Sandvik T1000 Drilling Rig - For Sale

Reichdrill T690 Drilling Rig - For Sale

Chicago Pneumatic T-672W Rotary Drilling Rig - For Sale

Schramm T64HB Drilling Rig-For Sale

Atlas Copco T3W Drilling Rig - For Sale

Ingersoll-Rand T3W Drilling Rig - For Sale

Acker AD-II Drilling Rig - for Sale

1500HP Drilling Rig for Sale

1400HP Oilwell 840E Drilling Rig - For Sale

CME 55 Drilling Rig-For Sale

Tension Machines for Cable / Wire / Rope - For Rent